10

10

SINAMICS V20

基本应用的**解决方案SINAMICS V20,满足通用需求的多功能变频器。现如今,工厂与机械制造业的自动化需求日益增多。传统的集成式控制系统被逐渐分割为独立的运动控制过程,相应简化了每个工艺步骤的复杂性。

西门子推出的基本型变频器SINAMICS V20 针对此类应用为用户提供了简易、经济的驱动解决方案。SINAMICS V20 具有调试过程快捷、易于操作、稳定可靠以及经济高效的特点。该款变频器有四种外形尺寸可供选择, 输出功率覆盖0.12 kW ~ 15 kW。高可靠性设计,创新的冷却设计,经久耐用。

*调试软件,通过简单参数设定即可实现预定功能。内置常见的连接宏与应用宏,简化操作,开箱即用。丰富的I/O接口,直观的LED面板显示,完善的集成功能,可以方便地应用在风机,水泵,传送装置及搅拌机、混料机等设备中。同时,创新的节能方式及节能结果显示,真正意义上节省费用。

成本较小化工艺设计、调试和操作成本以及运行过程中产生的其他成本都必须尽可能的低。针对这一点,SINAMICS V20 必定是您的较佳选择。此款变频器所配备的控制技术能够通过自动减少磁通来实现较佳的能量效率。不仅如此,变频器还可以显示实际的能耗数值同时提供额外的节能功能。由此大幅度地降低能耗。

典型应用

风机、泵类应用

? 离心泵

? 风扇

? 压缩机等

SINAMICS V20提供强大的常见的风机,水泵类应用功能及强大的保护功能,非常适合此类应用。

? 水泵气穴保护

? 针对水泵堵塞的多脉冲高转矩启动以及防堵模式

? 用于调节工艺数值的PID控制器(例如,温度、压力、水平、流量)

? 多泵控制功能通过额外增加两个定速驱动(级联)来扩大流量范围

? 霜冻和冷凝保护功能防止电机在较端环境条件下受潮

搬运类应用

? 带式输送机

? 辊式输送机

? 链式输送机

SINAMICS V20丰富了在启动加速和制动停止应用上的功能,大大方便了搬运类的应用。

? 斜坡时间可调,平稳加速,减少对对齿轮单元,轴承,滚筒和辊轴的压力

? 单脉冲高转矩启动功能适用于带有较高启动转矩的传送带

? 通过使用制动电阻或直流制动功能实现动态性能

? 通过监控负载转矩实现皮带损坏检测

加工类应用

? 加工制造业中的单个驱动。例如,轧钢机,搅拌机,捏炼机,破碎机,搅动机,离心分离机等

? 加工机器中带机械连动抽的主要驱动。例如,用于加工纺织品,绳索和线缆的环锭纱纺机,编织机等

对于连续加工类应用,SINAMICS V20强大的功能充分满足在高性能和节能方面的需求。

? 异常不停机模式能够保证不间断的加工生产,从而实现较高的生产率

? 通过共直流母线对再生能量进行转换

? 单脉冲高转矩启动功能适用于带有较高启动转矩的机器

? 适合于纺织的摆频功能

产品亮点及客户受益:

易于安装

? 安装方式多样

- 壁挂式安装及穿墙式安装均可实现紧凑的并排安装

- *额外组件即可正常运行

? 通讯灵活

- 变频器端子可用作通讯端口

- 连接宏中预设了用于USS和MODBUS RTU通讯的参数,调试便捷

? 制动高效

- 集成直流制动,复合制动

- 通过制动单元及制动电阻可实现能耗制动,且制动电阻占空比可在5 %到100 %之间 调节

- ≥ 7.5 kW的变频器集成内置制动模块,此类变频器可以直接连接制动电阻

易于使用

? 参数克隆/版本升级

- 使用BOP(基本操作面板)接口模块或参数下载器(使用参数下载器可不接主电源)能够轻松实现两台变频器之间的参数传输,缩短及简化调试过程

? 宏方法

- 内置常用的连接宏与应用宏,简化配置,快速调试

? 稳定可靠

- 更宽的电压范围、更好冷却设计以及带涂层的PCB板大大提升了变频器在恶劣环境中的稳定性

- 保证在以下总线电压范围内可靠运行:

- 1AC 200 V … 240 V (-10 % / +10 %)

- 3AC 380 V … 480 V (-15 % / +10 %)

- 运行时的环境温度较高可达60 °C

节约成本

? 运行过程中节能——ECO模式

- 内置用于V/f和V2/f控制的节能模式通过自动调节磁通电流实现节能

- 变频器支持以kWh、CO2甚至当地货币单位来显示能耗数值

? 运行过程中节能——DC共联

- 相同额定功率的SINAMICS V20变频器可以共用同一直流总线,能量再利用

- 减少对能耗制动以及外接组件的需求

? 运行过程中节能——休眠模式

- 变频器和电机仅在工厂或机器需要时才运行

- 节能,延长电机使用寿命

功率范围0.12 kW ~ 15 kW

电压范围1AC 200 V ... 240 V ( -10 % / +10 % )

3AC 380 V ... 480 V ( -15 % / +10 % )

控制模式V/f V2/f FCC

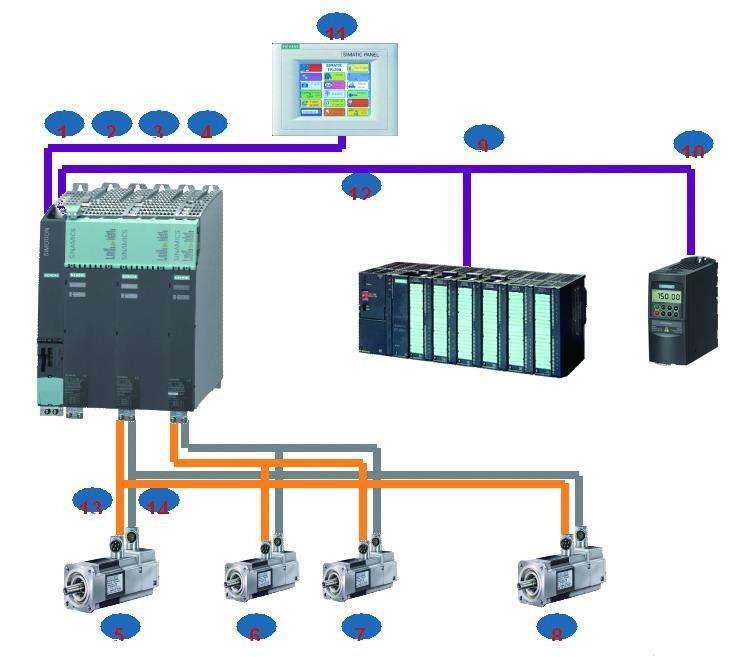

Different CPUs with integral PROFIBUS DP interfaces are available for different performance ranges. Depending on type, they are also available with integral PROFINET interface. The PROFIBUS interface enables the connection of up to 125 PROFIBUS DP slaves. Up to 256 PROFINET IO devices can be connected to the PROFINET interface. All CPUs of the SIMATIC S7-400 can handle extremely large configurations. In addition, several CPUs can work together in multicomputing in one central controller to increase performance. The CPUs enable short machine cycle times by means of their efficient processing speed and deterministic response times.

Signal modules (SMs) for digital (DI/DO) and analog (AI/AO) input/output

Communications processors (CPs), e.g. for bus connection and point-to-point connections

Function modules (FMs):

The specialists for demanding tasks such as counting, positioning and cam control.

The following can also be used depending on requirements:

Interface modules (IMs):

for connecting central controllers and expansion units. The central controller of the SIMATIC S7-400 can be operated with up to 21 expansion units.

SIMATIC S5 modules:

All input/output modules of the SIMATIC S5-115U/-135U/-155U can be addressed in the relevant SIMATIC S5 expansion units. In addition, the use of certain IP and WF modules of the SIMATIC S5 is possible both in S5 EUs and direct in the CC (using adapter casing).

Expansion

If users require more than one central controller for their applications, the S7-400 can be expanded:

Max. 21 expansion units:

Up to 21 expansion units (EUs) can be connected to the central controller (CC).

Connection of the interface modules (IMs):

The CC and EUs are connected via send and receive IMs. Send IMs are plugged into the CC, and the associated receive IMs are plugged into the downstream EUs. Up to 6 send IMs can be plugged into the CC (of which up to 2 with 5-V transfer), and up to 1 receive IM can be plugged into the EUs. Each send IM has 2 interfaces for connecting one line each. Up to 4 EUs (without 5-V transfer) or 1 EU (with 5-V transfer) can be connected to each interface of a send IM.

Fixed slot for power supply modules:

Power supply modules must always be plugged in on the extreme left in the CC and EUs.

Restricted data exchange via C bus:

Data exchange via the C bus only between the CC and six EUs (EU 1 to EU 6).

Central expansion:

To be recommended for smaller setups or control cabinets direct at the machine. The 5-V power can optionally also be supplied.

Max. distance between CC and the last EU of a line: 1.5 m with 5 V transfer, 3 m without 5 V transfer.

Distributed expansion with EUs:

Recommended in plants covering a large area where several EUs are located at individual locations. Up to S7-400 EUs or SIMATIC S5 EUs can be used.

Max. distance between CC and the last EU of a line: approx. 100 m with S7 EU, 600 m with S5 EU.

Note For distributed connection of S5 expansion units to an S7-400:

The IM 463-2 can be used in the CC of the S7-400, and an IM 314 is used in the S5 EU. The following S5 EUs can be connected to an S7-400:

EG 183U

EG 185U

EG 186U

ER 701-2

ER 701-3

Connection type

Maximum (total) cable length

Local link with 5-V transfer via IM 460-1 and IM 461-1

1.5 m

Local link without 5-V transfer via IM 460-0 and IM 461-0

5 m

Remote link via IM 460-3 and IM 461-3

102.25 m

Remote link via IM 460-4 and IM 461-4

605 m

Distributed expansion with ET 200:

recommended for plants covering extremely large areas. A line with up to 125 bus nodes can be connected via the PROFIBUS DP interface of a CPU. Maximum distance between the CC and last node on the line: 23 km (with fiber optic cable).

S7-400 communication

The SIMATIC S7-400 has different communication options:

Combined multipoint interface and DP master, integrated into all CPUs:

For the simultaneous connection of PGs/PCs, HMI systems, S7-200 and S7-300 systems and other S7-400 systems.

Additional PROFIBUS DP interface, integrated into several CPUs for cost-effective connection of distributed I/O systems, e.g. ET 200.

Integral PROFINET interface on PROFINET CPUs for connections to distributed I/O systems, or communication with other controllers and PC systems.

Communications processors for connecting to the bus systems PROFIBUS und Industrial Ethernet.

Communications processors for the powerful point-to-point connections.

Process communication via PROFIBUS DP

The SIMATIC S7-400 can be connected as master with PROFIBUS DP via the integral PROFIBUS DP interface of the S7-400-CPU (optional).

The following can be connected as masters on PROFIBUS DP:

SIMATIC S7-400 (CPUs, CP 443-5)

SIMATIC S7-300 (CPUs, CP 342-5 DP or CP 343-5)

SIMATIC C7 (via C7 with PROFIBUS DP interface or PROFIBUS DP CPs)

Although PG/PCs with STEP 7 or OPs are masters on the bus, they only use the PG and OP functions that also run in part via PROFIBUS DP.

The following can be connected as slaves:

Distributed I/O devices, e.g. ET 200

Field devices

SIMATIC S7-200, S7-300

C7-633/P DP, C7-633 DP, C7-634/P DP, C7-634 DP, C7-626 DP

SIMATIC S7-400 (via CP 443-5 only)

Data communication via multipoint interface (MPI)

The multipoint interface (MPI) is a communication interface integrated into the CPUs of the SIMATIC S7-400.

It is used for:

Programming and parameterization

HMI

Establishing simple network topologies involving equal communication partners

Variable connection options:

The MPI enables simultaneous connection of up to 32 nodes: